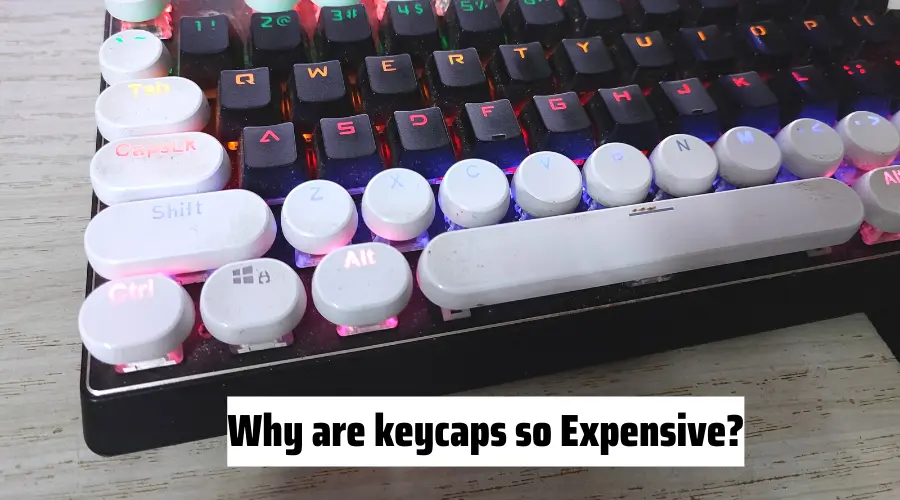

Keycaps are expensive based on the material used, such as PBT or ABS plastic, and the manufacturing process, such as double-shot molding or laser etching.

High-quality keycaps are also made with more intricate designs, which can increase their cost. Some keycaps are also limited edition, which can drive up their price due to rarity. Additionally, the demand for custom keycaps can also contribute to their cost.

In this post, I will explore in depth to understand why are mechanical keyboard keycaps so expensive. Let’s get started!

Keycap Material and Its Impact on Keycaps Price

When it comes to keycaps, the materials used can have a significant impact on both the cost and quality of the product. Here are some of the most common materials used to make keycaps and how they compare:

| Material | Cost | Durability | Feel |

| ABS | Cheaper and more common | Less durable, develop a greasy shine over time | Smooth |

| PBT | More expensive and less common | More durable, do not develop a shine over time | Textured |

ABS Plastic Keycaps

ABS plastic is the most common material used for keycaps due to its affordability. However, it is not as durable as other materials and is prone to becoming shiny and slippery over time.

PBT Plastic Keycaps

PBT plastic is a step up in quality and is known for its durability and resistance to shine. It is also more expensive than ABS plastic.

GMK Keycaps

Also, there is a case where ABS-made keycaps can be very expensive, e.g. GMK Keycaps. If you check their price you would find that the GMK keycaps are even more expensive than the PBT keycaps.

To get these premium GMK keycaps, you can look for keycap group buy as they are not easily available.

Manufacturing Processes and Their Impact on Keycaps Price

| Manufacturing Process | Relative Expense |

| Double-shot Molding | High |

| Dye-sublimation | High |

| Laser Etching | Medium |

| UV Printing | Medium |

Double-shot Molding

One of the most popular manufacturing processes for keycaps is double-shot molding. This process involves creating a two-part mold and injecting two different types of plastic into it.

The first shot creates the legend or symbol on the keycap, while the second shot creates the keycap itself. This process is more expensive than other methods but produces high-quality, durable keycaps that won’t wear out easily.

Double-shot keycaps are also resistant to fading and scratching, making them a popular choice among enthusiasts.

Dye-sublimation

Another manufacturing process used for keycaps is dye sublimation. This process involves printing the legend onto the keycap using a special dye that is then transferred to the plastic through heat and pressure.

Dye-sublimated keycaps are durable and long-lasting, but the process is time-consuming and requires specialized equipment, which can drive up the price.

Laser Etching

Laser etching is a process that involves using a laser to burn the legend or symbol onto the keycap’s surface. This process is fast and precise, but it can be expensive due to the specialized equipment required.

Laser-etched keycaps are also more susceptible to fading and wear over time, making them less popular among enthusiasts.

UV Printing

UV printing is a newer process that involves printing the legend onto the keycap using a special ink that is cured with UV light. This process is fast and produces high-quality, vibrant keycaps that won’t fade or wear out easily. However, the specialized equipment required for UV printing can make it more expensive than other methods.

Overall, the manufacturing process used for keycaps can have a significant impact on their price. Double-shot molding and dye-sublimation are popular choices among enthusiasts due to their durability and longevity, while laser etching and UV printing are newer processes that offer their own unique advantages.

Customization and Artisanship

One of the main reasons why keycaps can be so expensive is the level of customization and artisanship involved in their production. Custom keycap sets and artisan keycaps can significantly increase the price of a mechanical keyboard, but they also offer a unique and personalized touch that many enthusiasts value.

Custom Keycap Sets and Their Influence on Keycaps Price

Custom keycap sets are designed to fit specific mechanical keyboards and can be made from a variety of materials, including PBT and ABS plastics, as well as more exotic materials like metal and wood. The manufacturing process for custom keycaps can also vary, with some sets using double-shot molding or laser etching to create intricate designs and legends.

The level of customization and quality of materials used in custom keycap sets can greatly influence their price. Limited edition sets, in particular, can be highly sought after and drive up the price due to their rarity. Some popular designers and manufacturers of custom keycap sets include GMK, SA, and Signature Plastics.

Artisan Keycaps

Artisan keycaps are handmade keycaps that are often produced in small batches by independent designers and artists. These keycaps can be highly detailed and feature unique designs that are not typically found in mass-produced keycap sets.

Artisan keycaps are often made from resin or other materials and can feature intricate designs, such as miniature sculptures or hand-painted artwork. The level of artisanship involved in creating these keycaps can greatly influence their price, with some sets selling for hundreds of dollars or more.

Because artisan keycaps are often produced in small batches, they can be difficult to obtain and highly sought after by collectors and enthusiasts. Some popular artisan keycap designers include Jelly Key, Dwarf Factory, and Hot Keys Project.

Quality and Durability

When it comes to keycaps, quality, and durability are important factors to consider. The materials used, thickness, and manufacturing process all play a role in determining the overall quality and lifespan of the keycaps. Here are some sub-sections to consider:

The Importance of Keycap Thickness and Its Effect on Cost

The thickness of keycaps can affect their durability and overall feel. Thicker keycaps tend to be more durable and have a more satisfying typing experience. However, thicker keycaps can also be more expensive due to the increased amount of material used in their manufacturing process.

For example, keycaps made using double-shot molding, which involves injecting two different types of plastic to create the legend and the keycap, tend to be thicker and more durable than keycaps made using laser etching. As a result, double-shot keycaps are often more expensive.

The Lifespan and Wear Resistance of Different Keycap Materials

The material used in keycap manufacturing can also affect its lifespan and wear resistance. Most keycaps are made of plastic, with ABS and PBT keycaps being the most common types. ABS keycaps tend to be less expensive but are also less durable than PBT keycaps. PBT keycaps, on the other hand, are more expensive but also more durable and resistant to wear and tear.

Some keycap sets also use other materials such as metal or wood, which can add to the cost but also provide a unique look and feel. However, these materials may not be as durable as plastic and may require more maintenance to keep them looking and feeling their best.

The Role of Quality in the Overall User Experience and Satisfaction

When it comes to keycaps, quality is not just about durability and the materials used. It also plays a crucial role in the overall user experience and satisfaction. High-quality keycaps can improve the feel and sound of typing, providing a more satisfying experience for the user.

Furthermore, high-quality keycaps often come with more intricate designs and legends, which can enhance the overall aesthetic of the mechanical keyboard. This attention to detail can make a big difference in the user’s overall satisfaction and enjoyment of their keyboard.

Licensing and Intellectual Property

Licensed designs can be more expensive due to the costs associated with obtaining the license, while copyright and trademark laws can limit design options and increase production costs. Original designs are also important in maintaining the exclusivity and value of keycaps.

Licensed Designs and the Associated Costs

When it comes to keycaps, licensed designs are often more expensive due to the costs associated with obtaining the license. Keycap manufacturers must pay for the rights to use copyrighted or trademarked designs, which can be a significant expense. This cost is then passed on to the consumer in the form of higher prices.

The Impact of Copyright and Trademark on Keycap Pricing

Copyright and trademark laws also affect keycap pricing. Manufacturers must ensure that their designs do not infringe on existing copyrights or trademarks, which can limit their options and increase production costs. In addition, enforcing these laws can be expensive, which can also contribute to the cost of keycaps.

The Role of Original Designs in Maintaining Exclusivity and Value

Original designs are important in maintaining the exclusivity and value of keycaps. Keycap manufacturers invest significant time and resources into creating unique designs, which can be expensive. By maintaining the exclusivity of these designs, manufacturers are able to maintain their value and justify higher prices.

I’m Anirban Saha, Founder & Editor of TechBullish. With a B.Tech in Electronics and Communication Engineering, and 6+ years of experience as a software developer, I have expertise in electronics, software development, gadgets, and computer peripherals. I love sharing my knowledge through informational articles, how-to guides, and troubleshooting tips for Peripherals, Smart TVs, Streaming Solutions, and more here. Check Anirban’s Crunchbase Profile here.